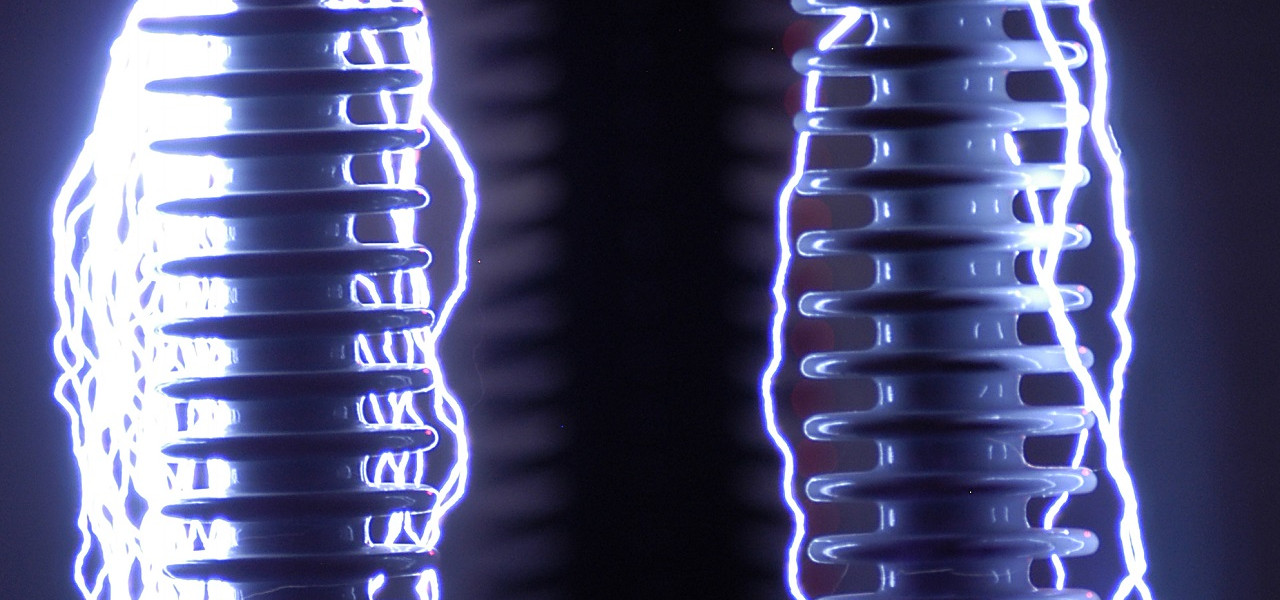

The purpose of HV bushings

is to provide a safely insulated entrance for an electrical conductor into a high-voltage device, such as power capacitors and transformers.

For oil/gas hermetically filled devices, bushings need to be leak free.

The challenge for a long lifetime

Bushings must keep hermeticity and insulating performances, withstanding:

- Any outdoor climatic condition

- Wide operating temperature range, from extreme cold to very hot environments

- Mechanical stresses in operation and maintenance activities

- Peak temperatures and mechanical stress during assembly to devices

- Rated voltage and current without partial/corona discharge, flashover and overheating

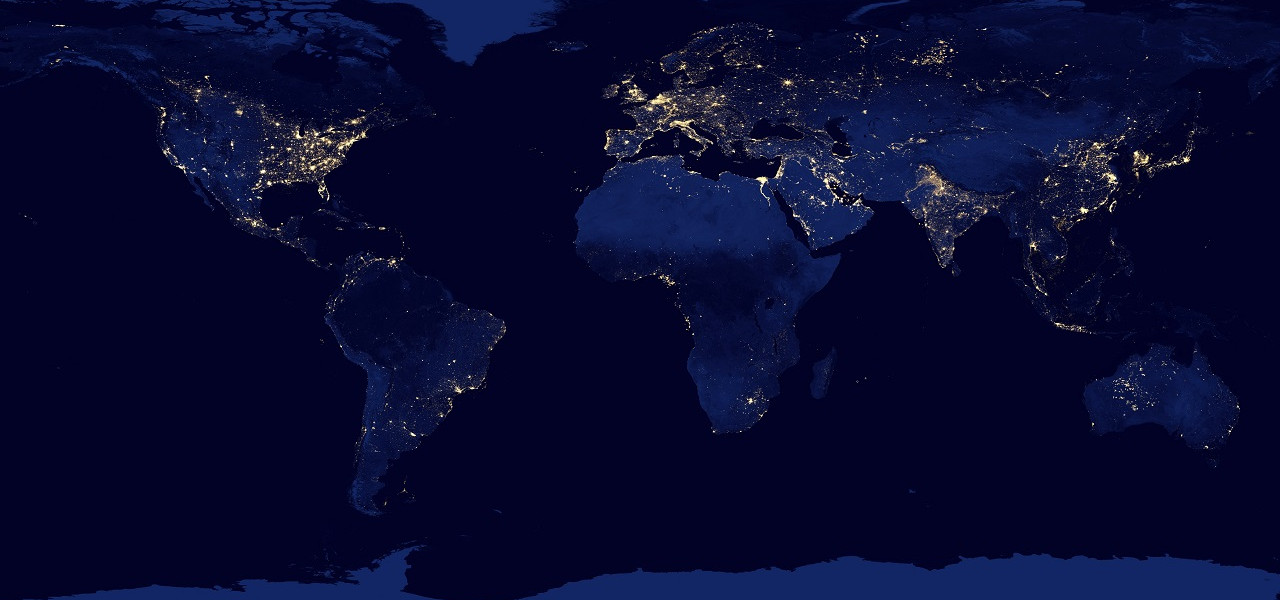

Zamber has the longest track record of capacitor bushings operating on field

We have been manufacturing hermetic bushings for more than 60 years, exporting to primar international capacitor manufacturers.

Some millions of Zamber bushings have been installed worldwide, giving us the longest track record of on field product duration.

We constantly perform rigorous tests on our products and on our production processes so to keep the highest quality and European standards standards.

Our wide product range is based on different technologies: Metallized Bushings and Rubber Seal bushings.

As range completion, Assembled bushings delivered with kit of metal parts and gaskets for self assembly and rubber bird caps as accessories.

We supply our bushings in a big number of variants, and on request, our R&D develops customized products or variants following customer’s indication.

Withstand operating temperature down to -60°C and up to 130°C

BEST ELECTRICAL PERFORMANCES

No sharp edges minimize corona effects and radio influence voltage activity

BEST METAL MATERIALS

High grade stainless steel AISI316L, AISI304L and brass CW617

100% LEAK TESTED

Every bushings coming out from our factory has been leak tested at 6 bars

TESTED SEAL QUALITY

Low absorption and best rebounding tests for rubber seals

High adhesion traction tests for metallization

TOP RELIABILITY OF ELECTRICAL TESTS

Electrical tests are performed at CESI, primar European laboratory

FREQUENT MECHANICAL TEST

Mechanical tests are frequently carried out at Zamber

Test procedures have been assessed by CESI lab

HIGHEST MECHANICAL RESISTANCE

Cantilever 1000N

Cantilever 1000N under pressure

Torque 45Nm

Traction 1000N

MADE IN EUROPE

RELIABLE TECHNOLOGY

Metal parts are fastened to porcelain by means of metallizing/soldering or by means of our patented spinning technology. A qualified retaining resin, where applied, is just for added security

LONG OPERATING LIFE

In 60 years activity, we placed on field millions of bushings… still in service..!

BEST PORCELAIN QUALITY

High resistance mass and best glaze quality. They also look good!

FREE OF DIELECTRIC FLUID CONTAMINATION

All materials in contact with dielectric oil are contamination free

ECO-FRIENDLY

Product is compliant to RoHS, Reach, Dodd’s Act and Conflict free following European standards